Top 5 Benefits of Woven Geotextile Fabrics in Roads

Discover the top 5 advantages of woven geotextile fabrics in road construction, from soil reinforcement to drainage. Learn more with Satyendra Packaging.

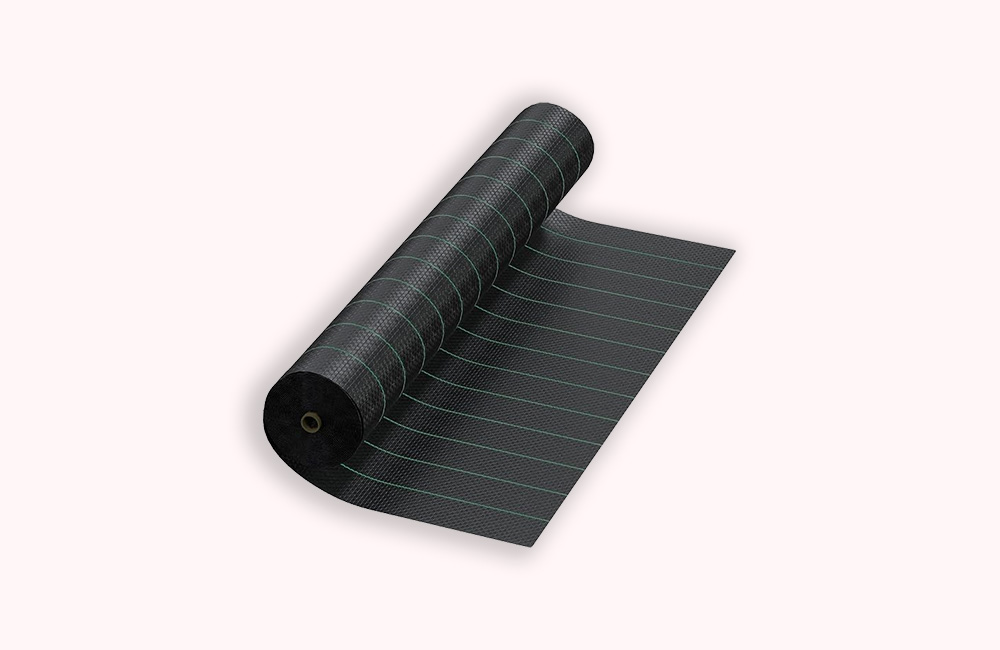

Building strong, long-lasting roads is essential for any developing nation. While concrete and asphalt are the stars of the show, there's a hidden hero working beneath the surface: Geo-Textile Fabrics. Specifically, woven Geo-Textile Fabrics are becoming indispensable in modern road construction. At Satyendra Packaging, we understand the critical role these materials play in ensuring road durability and performance. Let's explore the top five advantages of using woven Geo-Textile Fabrics in your next road project.

One of the primary benefits of woven Geo-Textile Fabrics is their superior separation capability. When placed between different layers of soil or aggregate, they prevent intermixing. This is crucial in areas with soft subgrades, as it stops the road's base material from sinking into the weaker soil, maintaining the integrity and strength of the road structure.

Secondly, these fabrics excel at reinforcement. Woven Geo-Textile Fabrics have high tensile strength, meaning they can withstand significant pulling forces. By distributing loads more evenly across the roadbed, they effectively reinforce the soil, reducing stress concentrations and minimizing the formation of ruts and cracks. This leads to a longer-lasting road that requires less maintenance.

Thirdly, filtration is another key advantage. Woven Geo-Textile Fabrics allow water to pass through while preventing the migration of fine soil particles. This is vital for drainage systems within the road structure, preventing water buildup that can weaken the road and lead to premature failure. Proper filtration ensures the stability of the subgrade.

Their protection capabilities are also noteworthy. Woven Geo-Textile Fabrics act as a protective layer, shielding geomembranes or other sensitive materials from damage caused by sharp aggregates or construction equipment. This added layer of defense extends the lifespan of underlying components, contributing to the overall longevity of the road.

Finally, the cost-effectiveness of woven Geo-Textile Fabrics is a significant draw. While there's an initial investment, the long-term benefits in terms of reduced maintenance, extended road life, and improved performance far outweigh the cost. By preventing common road issues like rutting and cracking, these fabrics lead to substantial savings over the lifetime of the road.

In conclusion, the integration of woven Geo-Textile Fabrics into road construction offers a multitude of benefits, from enhancing structural integrity to ensuring optimal drainage. For robust and enduring roads, choosing high-quality Geo-Textile Fabrics from Satyendra Packaging is a smart investment.

Recent Blogs

- Pinch Bottom Bags: Why Brands Are Switching to This Smart Packaging?

- FIBC vs. Rigid Containers: Which One Delivers Better ROI for Bulk Transport?

- The Rise of Flexible Packaging: What Manufacturers and Startups Must Know

- What Is PP Multifilament Yarn? Benefits, Uses, and Industry Applications

- Polypropylene (PP): Uses, Benefits, and Applications in Packaging Industry

- Leno Bags: A Stronger Packaging Backbone for India’s Farm Produce Market

- The Ultimate Guide to Choosing the Geotextile Fabric for Your Project

- Top 6 Best Packaging Materials for Bulk Goods: Strong & Sustainable

- What is Flexible Packaging? The Smart Choice for FMCG Export & Supply

- Complete Guide to FIBC Bags – Types, Uses, and Benefits You Should Know

- BOPP Laminated Woven Bags Benefits | Satyendra Packaging

- Innovative BOPP Film | Satyendra Packaging Ltd Manufacturing

- BOPP Pinch Bottom Bags | Reliable Custom Packaging

- BOPP Laminated PP Woven Sacks | Durable Custom Packaging

- Leno Bags for Fresh Produce – Breathable & Durable Packs

- PP Woven Fabric: Meaning, Properties & Applications Guide

- FIBC Jumbo Bags: Uses, Benefits & More | Satyendra Packaging

- High-Quality BOPP Film Packaging | Satyendra Packaging India

- Are BOPP Films Safe for Food Packaging? | Satyendra Group

- Are FIBCs Recyclable? A Guide to Sustainable Bulk Bags

- BOPP/PP Block Bottom Bags: Types, Benefits & Industry Uses

- Why PP Multifilament Yarn is Essential for Multiple Industries

- Boost Your Business with BOPP Bags

- Knitted Geotextiles: Game-Changer in Civil Engineering Solutions

- How Flexible Packaging Solutions Help to Grow Business

- FIBC Bags: The Versatile Solution for Bulk Material Handling

- Types of Flexible Packaging and Their Advantages

- Reasons Why PP Leno Mesh Bags Are the Best Choice for Produce Packaging

- Why BOPP Laminated PP Woven Bags Are Right For Your Business?

- Woven Polypropylene Bags: The Complete Guide

- Exploring the Benefits of FIBC Bulk Bags: A Practical Guide