Knitted Geotextiles: Game-Changer in Civil Engineering Solutions

Explore the versatility of knitted geotextile fabrics in civil engineering and environmental protection. Learn about their flexibility, durability, and applications.

Knitted Geo Textile Fabrics: Revolutionizing Civil Engineering and Environmental Protection

In the world of civil engineering and environmental protection, geotextiles play a critical role in improving the durability and performance of infrastructure. Among the various types of geotextiles, knitted geotextile fabrics have emerged as an innovative solution, providing a range of benefits for soil stabilization, erosion control, drainage systems, and more. Satyendra Packaging Limited crafted these fabrics through a unique knitting process, offering distinct advantages over traditional woven and non-woven geotextiles.

In this blog, we will explore the properties, applications, and benefits of knitted geotextile fabrics and why they are becoming a preferred choice in the construction and environmental sectors.

What Are Knitted Geo Textile Fabrics?

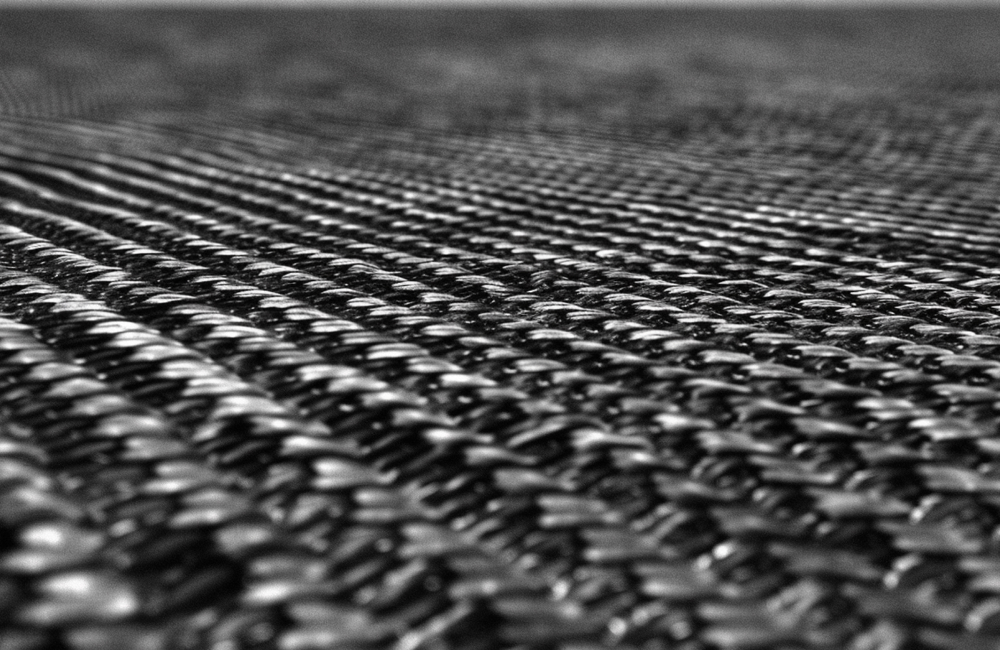

Knitted geotextile fabrics are produced using a specialized knitting process, where threads or yarns are interlocked in a consistent pattern to create a fabric. Unlike woven fabrics, which involve interlacing two sets of yarns at right angles, knitted fabrics are created by interlocking loops of yarn, resulting in a more flexible and stretchable material. This gives knitted geotextiles unique characteristics that make them suitable for specific applications in civil engineering and environmental protection.

Key Characteristics of Knitted Geo Textile Fabrics

- Flexibility and Stretchability One of the standout features of knitted geotextiles is their flexibility. The interlocking loops of yarn allow the fabric to stretch and conform to various shapes and surfaces. This characteristic is especially useful in applications where the fabric needs to accommodate movement or deformation, such as in erosion control projects or soil reinforcement.

- High Durability Knitted geotextiles are designed to withstand harsh environmental conditions. The knitted structure provides excellent tensile strength, making the fabric resistant to tearing and puncturing. This durability ensures that the fabric can endure the stresses and strains associated with heavy construction equipment, soil movement, and extreme weather conditions.

- Enhanced Drainage Properties The open structure of knitted fabrics promotes efficient water flow through the material, making them ideal for drainage applications. The fabric allows water to pass through while preventing soil erosion, which is particularly beneficial in applications such as road construction, embankments, and landfills.

- Lightweight Yet Strong Knitted geotextiles offer a balance of lightweight construction and strong performance. Their reduced weight makes them easier to handle and install, yet they still provide the strength needed to support large-scale infrastructure projects.

- Resistance to Chemical Degradation Geotextiles used in environmental protection must be able to withstand exposure to various chemicals, including oils, acids, and alkalis. Knitted geotextile fabrics are highly resistant to chemical degradation, making them suitable for use in industrial applications, landfills, and other environments where chemical exposure is a concern.

Applications of Knitted Geo Textile Fabrics

Knitted geotextile fabrics have a wide range of applications across various industries. Some of the most common uses include:

- Soil Stabilization and Reinforcement Knitted geotextiles are often used to reinforce weak or unstable soils, providing additional strength and stability. They are commonly used in road construction, railway embankments, and slope stabilization projects. The fabric helps distribute the load evenly, preventing soil movement and reducing the risk of erosion.

- Erosion Control Erosion is a significant concern in areas with heavy rainfall or wind, especially in coastal regions, riverbanks, and steep slopes. Knitted geotextiles are used to prevent soil erosion by stabilizing the soil surface and allowing vegetation to grow. The fabric provides a protective barrier that prevents soil from being washed away by water while allowing water to pass through.

- Drainage Systems The excellent drainage properties of knitted geotextiles make them ideal for use in drainage systems. They are commonly used in the construction of roadways, landfills, and retaining walls, where proper water management is crucial. The fabric helps facilitate water flow, preventing the accumulation of water that could compromise the integrity of the structure.

- Landfill Liners and Covers Knitted geotextiles are used in landfills to provide a protective layer that prevents the leakage of contaminants into the surrounding environment. The fabric serves as a barrier, ensuring that harmful substances do not seep into the soil or groundwater. Additionally, the drainage capabilities of knitted geotextiles help manage leachate and groundwater flow in landfill systems.

- Reinforced Concrete Structures In certain applications, knitted geotextiles are used to reinforce concrete structures, such as bridges, tunnels, and foundations. The fabric helps distribute the load more evenly, improving the strength and longevity of the structure. It also provides a protective layer against moisture and chemical degradation, extending the lifespan of the concrete.

Benefits of Using Knitted Geo Textile Fabrics

- Cost-Effectiveness Knitted geotextiles are often more cost-effective compared to other types of geotextiles, such as woven fabrics. Their lightweight nature reduces transportation and installation costs, making them an attractive option for large-scale projects.

- Environmental Sustainability The use of knitted geotextiles contributes to environmental sustainability. The fabric helps prevent soil erosion, protects natural resources, and promotes the growth of vegetation. Additionally, many knitted geotextiles are made from recycled materials, further reducing their environmental impact.

- Improved Performance and Longevity Knitted geotextiles are designed to perform well in challenging conditions, offering long-lasting durability and resistance to wear and tear. This reduces the need for frequent maintenance or replacement, making them a more reliable and cost-effective solution in the long term.

- Ease of Installation The lightweight nature of knitted geotextiles makes them easier to handle and install. They can be quickly deployed in a variety of applications, reducing labor costs and project timelines.

Knitted geotextile fabrics are a versatile and innovative solution for various civil engineering and environmental applications. Their flexibility, durability, and excellent drainage properties make them ideal for soil stabilization, erosion control, drainage systems, and more. As the demand for sustainable and cost-effective materials grows, knitted geotextiles are likely to play an even more significant role in shaping the future of infrastructure and environmental protection.

By incorporating knitted geotextiles into construction and environmental projects, industries can ensure the long-term stability and safety of their structures while contributing to a more sustainable and resilient future.

Recent Blogs

- FIBC vs. Rigid Containers: Which One Delivers Better ROI for Bulk Transport?

- The Rise of Flexible Packaging: What Manufacturers and Startups Must Know

- What Is PP Multifilament Yarn? Benefits, Uses, and Industry Applications

- Polypropylene (PP): Uses, Benefits, and Applications in Packaging Industry

- Leno Bags: A Stronger Packaging Backbone for India’s Farm Produce Market

- The Ultimate Guide to Choosing the Geotextile Fabric for Your Project

- Top 6 Best Packaging Materials for Bulk Goods: Strong & Sustainable

- What is Flexible Packaging? The Smart Choice for FMCG Export & Supply

- Complete Guide to FIBC Bags – Types, Uses, and Benefits You Should Know

- BOPP Laminated Woven Bags Benefits | Satyendra Packaging

- Innovative BOPP Film | Satyendra Packaging Ltd Manufacturing

- BOPP Pinch Bottom Bags | Reliable Custom Packaging

- BOPP Laminated PP Woven Sacks | Durable Custom Packaging

- Leno Bags for Fresh Produce – Breathable & Durable Packs

- PP Woven Fabric: Meaning, Properties & Applications Guide

- FIBC Jumbo Bags: Uses, Benefits & More | Satyendra Packaging

- Top 5 Benefits of Woven Geotextile Fabrics in Roads

- High-Quality BOPP Film Packaging | Satyendra Packaging India

- Are BOPP Films Safe for Food Packaging? | Satyendra Group

- Are FIBCs Recyclable? A Guide to Sustainable Bulk Bags

- BOPP/PP Block Bottom Bags: Types, Benefits & Industry Uses

- Why PP Multifilament Yarn is Essential for Multiple Industries

- Boost Your Business with BOPP Bags

- How Flexible Packaging Solutions Help to Grow Business

- FIBC Bags: The Versatile Solution for Bulk Material Handling

- Types of Flexible Packaging and Their Advantages

- Reasons Why PP Leno Mesh Bags Are the Best Choice for Produce Packaging

- Why BOPP Laminated PP Woven Bags Are Right For Your Business?

- Woven Polypropylene Bags: The Complete Guide

- Exploring the Benefits of FIBC Bulk Bags: A Practical Guide