Geo-Textile Fabrics

Introduction

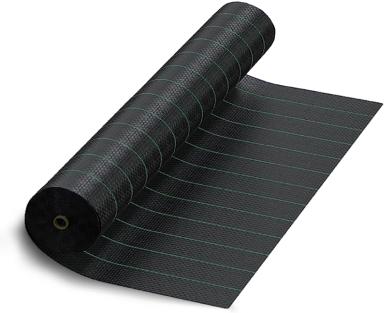

Geo textile fabrics are a key category within geosynthetics and are primarily classified into three types: woven geotextile, non-woven geotextile, and knitted. These geo fabric textile types are manufactured using different yarns with diverse properties tailored to specific end-use requirements. Our specialization lies in woven geotextile and knitted variants. The multiple functions of geotextile fabrics include separation, filtration, drainage, reinforcement, barrier creation, and protection. Whether you’re working with geotextile fabric for infrastructure or landscaping, the choice between woven geotextile and non-woven geotextile fabric plays a crucial role in performance and durability.

Key Features & Applications of Geotextile Fabric

Geotextile Fabric Uses in Construction & Infrastructure

- a) Reinforcement on Weak Soils

- b) Separation/Filtration Layers

- c) Drainage

- d) Pavement Reinforcement

- e) Slope Protection

- f) Rock-fall Protection

Geotextile Sheet & Membrane Applications for Airfields

- a) Runway Reinforcement

- b) Drainage

Agriculture Uses of Non-Woven Geotextile Fabric

- a) Soil Protection

- b) Protection against

- c) Unwanted weed and insects

Woven Geotextile for Retaining Structures & Containment Walls

- a) Reinforcement

Geotextile Membranes for Reservoirs, Canals & Dams

- a) Lining

Geotextile Fabric for Coastal & Riverbank Protection

- a) Erosion & Sediment

Manufacturing Process of Woven & Non-Woven Geotextiles

Synthetic or natural fibers are used in the creation of geotextiles to produce a substance that resembles fabric. There are several ways to create geotextiles, such as:

- Needle punching: This technique makes non-woven fabric by punching needles through layers of fibers to bind and interlock them.

- Thermal bonding: This technique involves melting fibers together using heat to form a bond between them.

- Chemical bonding: By using chemicals to fuse the fibers together, a robust and long-lasting material can be produced.

- Weaving: To make woven cloth, strands are interlaced during the weaving process.

- Knitting: Using this technique, yarns are looped to create a knitted fabric.

After the geotextile is manufactured, it can undergo additional processing to form it into rolls or sheets.

Material Composition of Geotextile Sheets, Membranes & Fabrics

The main component of geotextiles are formed of polypropylene, while other polymers such as polyester, high density polyethylene, polyamide (nylon), and polypropylene can also be used in combination.

Types of Geotextile Fabrics We Manufacture

- Woven Essentially, woven geotextile is made by weaving individual yarns on a loom to create a uniform length. Different materials such as slit films, fibrillated yarn, and monofilaments can be used, but the weaving technique is constant regardless of the material used.

- Knitted Knitted geotextiles are manufactured by the process of interlocking a series of loops of yarn together. All of the knitted geosynthetics are formed by using the knitting technique in conjunction with some other method of geosynthetics manufacture, such as weaving.

Why Choose Satyendra Packaging Limited as Your Geotextile Manufacturer?

Our specialty lies in producing high-quality ground covers, shading nets, road covers, etc. of the highest quality. We have around 30 Sulzer looms dedicated to woven and knitted geotextiles for numerous applications.

With a dedicated production facility for Geotextiles, we can manufacture up to 300 Tonnes of Geotextiles in a month. This includes all the categories of Geotextiles that we are capable of producing.

At Satyendra Packaging Limited, our decades of experience as a geo-textile manufacturer in India give us a significant edge over the competition. With our large production capacity, we efficiently manufacture high-quality geo textile material, positioning us among the top geo-textile fabric suppliers in India and trusted geotextile fabric manufacturers India relies on.

What are the main types of geotextile fabrics?

There are two primary types of geo fabric textile:

- Woven geotextile - made by interlacing synthetic fibers, offering high strength for reinforcement applications.

- Non woven geotextile fabrics - produced using bonding techniques, ideal for filtration, drainage, and separation purposes.

Why is geotextile fabric important for environmental sustainability?

Geotextile fabrics play a crucial role in sustainable construction by preventing soil erosion, improving water drainage, and reinforcing infrastructure without excessive material use. High-quality geo textile materials from trusted geotextile fabric manufacturers India help build eco-friendly solutions for roads, slopes, and water management projects.

Why choose Satyendra Group as your geo-textile fabric manufacturer in India?

Satyendra Group is a leading geo-textile fabric manufacturer with expertise in woven and non woven geotextiles fabric production. With a capacity of 300 tonnes per month, they supply durable geo textile materials for applications such as slope stabilization, airfield runways, and erosion control.

Where can I find reliable geo-textile fabric suppliers in India?

If you need premium geo-textile fabric suppliers in India, Satyendra Group offers high-quality geotextile fabrics for various construction and infrastructure projects. Their geo-textile fabric suppliers ensure optimal strength, durability, and cost-effectiveness for all engineering needs.

How does geotextile material benefit infrastructure projects?

High-quality geo textile material enhances infrastructure development by improving soil stability, preventing erosion, and optimizing water drainage. Whether using woven geotextile for roadways or non woven geotextile for water filtration, these fabrics support long-term durability in construction.