BOPP Packaging & Industrial Films

Introduction

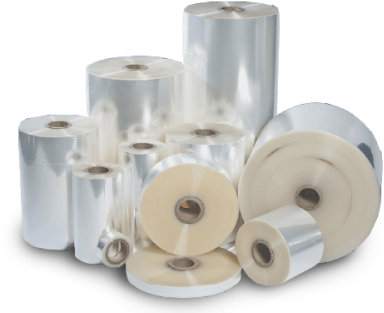

At Satyendra Packaging Limited -BOPP Division, we are committed to delivering highly advanced and diverse types of BOPP film to meet the evolving needs of the flexible packaging industry. Our Plant manufactures a comprehensive range of BOPP rolls and films, including transparent BOPP film, heat-sealing film, and matte film. We also specialize in innovative variants such as SIT films at 75°C, 85°C, 95°C, and 105°C, high seal strength grade films, low COF BOPP films (< 0.18), and high COF BOPP films (> 0.80).

Additionally, our product lineup includes smooth and matte release grade film, along with metalized grade BOPP film featuring both standard and high-barrier properties — MVTR < 0.1 and OTR < 0.20 — and low SIT metallized options (75°C / 85°C / 95°C / 105°C) with superior sealing resistance.

- At SPL, we produce the BOPP Film on a 10.4 meter BOPP line from Brueckner with a line speed of 600 MPM and a production capacity of 54000 MT p.a., specially designed and longer TDO, and MDO for better thermal stabilization of the film.

- Specially designed casting unit for better film clarity, Line is capable of producing 10–60 micron film.

- Specially designed co-extruder for producing the best quality matte film. The higher diameter capacity of the winder enables it to produce an extra-long film reel.

- We produce a metalized film on a 3.650 meter-wide metallizer line, which is from BOBST. The metallizer is equipped with Alu-Bond technology. It enhances the barrier property by 4-5 times and metal bond strength by 5-6 times in comparison to the normal metalized film.

- Capable of producing 10–50 micron BOPP film, capable of coating 0.40 OD to 3.0 OD metalizing film, and in addition to this, our equipped metallizer is specialized with the plasma metalizing facility.

At SPL, the existing BOPP Line comprises a 3-layer extruder line of BOPP film, which makes three-layer BOPP film jumbo by hot melting raw materials such as polypropylene granules and PP base additive compound. The film goes through specially designed and longer TDO and MDO facilities for better thermal stabilization of the film. Once BOPP Jumbo Roll has been ready, it is slit on the primary slitter facility, which comprises and designs a Bonded Friction Chuck to better grip the rewind reels. It has helped to produce good quality reels, which is suitable for 8”, 6", and 3” cores, Upon the readiness of material, our plant is equipped with an automatic reel conveying system for both primary as well as secondary slitters. Slit reels are conveyed automatically through a motorized roller conveyor, and weighing of the slit reels is done automatically in the highly precise Mettler Toledo weighing modules and finally packed on the automatic conveyor.

For BOPP Filmweare using Polypropylene Granules, PP Base Additive Compound and other co-polymer material and for Metallized BOPP Film we are using Polypropylene Granules, PP Base Additive Compound and Evaporation Boats, which resulted the finish product such as Transparent BOPP Film, Matte BOPP Film, Metallized BOPP Film along with a special range of products such as SIT 75°C low grade films / 85°C / 95°C / 105°C, High Seal Strength Grade Films, Low COF Bopp Films - 0.80, Smooth and Matte Release Grade Film, etc.

- Transparent Heat Sealable Film (Both side sealable) with variant of SIT 105°c/95°c/85°c/75°c Seal initiation Temperature.

- Transparent Heat Sealable Film (Single side sealable).

- Transparent Non Heat Sealable Film.

- Matte Heat Sealable Film with Heat seal initiation Temperature in range of 105°c-110°c. on matte side.

- Matte Heat Sealable Film with Heat seal initiation Temperature of 123c. on matte side.

- Matte Non Heat Sealable Film.

- Metallized Heat Sealable Film with variant of 105°c/95°c/85°c/75°c Seal initiation Temperature.

- Metallized sandwich grade Non Heat Sealable Film.

- Crack Resistance Metallized Film.

- Matte Metallized Heat Sealable Film.

| Film Description | Product Grade | Microns produced on line | Application |

|---|---|---|---|

| Bopp Transparent Non heat sealable film one side/both side corona treated for printing and lamination grade | TN1-PL/TN2-PL | (12, 15,18, 20, 25, 30, 35, 40, 45, 50) | For Printing & Lamination for bakery confectionery, snacks, Lamination for magazine, boxes & books |

| Heat Sealable BOPP film one side corona treated grade- Normal heat sealing range 85° / 95°/ 105° Celsius. | TH1-LTS (105° Celsius)/ TH1-LLTS (95° Celsius)/ TH1-ULTS (85° Celsius) | (15, 18, 20, 25, 30, 40, 45, 50) | Printing & Lamination, snacks, food & Confectionery |

| Transparent BOPP Film for Wrap around Label | TN1-LB | (25, 30, 35, 40) | For Wrap around bottle labels |

| Transparent BOPP film for adhesive tape | TN1-AT/TN1-TG | (23, 25, 28, 30, 35, 37, 40, 45, 50) | Pressure sensitive Adhesive Tape/Carton sealing tapes, Textile bags |

| Matte BOPP one side/ both side corona treated grade | MN1-PL/ MN2-PL | (12,15,18, 20, 25, 30, 35, 40, 45, 50) | For Printing & Lamination for bakery confectionery, snacks |

| Matte BOPP film Non Seal high Cof film | MN1-HCF | (18, 20, 25, 30) | Printing & Lamination, Chocolate, Ice cream |

| Matte BOPP Film one side Matte & other side Glossy & corona treated Heat Sealable | MH1-PL | (15, 18, 20, 25, 30, 35) | Printing & Lamination of Bakery/ Chips & Snacks/ Confectionery |

| Antifog BOPP Film sealable both side treated | TH2-AF | (20, 25, 30, 35, 40) | Hot & Cold Anti-fog Application,Fresh food & Vegetable packaging |

| BOPP Heat sealable high Cof grade film | TH1-HCF | (17, 18, 20, 25, 30, 35) | Pert Food, Rice bags, heavy duty bags |

| BOPP Heat Sealable Low Cof film | TH1-LCF | (15,18, 20, 25, 30, 35, 40) | Bakery, Snacks confectionery, Biscuits bundle wrap |

| Metallized BOPP film Both side heat seal one side corona treated grade | VMH1-LTS | (15, 18, 20, 25, 30) available in another microns as well | Printing & Laminationfor Biscuits, Cookies, Confectionery Pouches |

| Metallized Non Sealable film for Printing and Wrapping, For Carton lamination grade, decorative gift packs, flower over wraps etc. | VMN1-WG | (12, 15, 17, 18, 20, 25, 30, 35) | Flower wrap application. Paper board lamination |

| Metallized Non sealable for sandwich application | VMN2-SW | (15, 18, 20, 25) | Sandwich lamination for 3 ply pack structure for Biscuits, Cookies, Crackers confectionery |

| Metallized Heat sealable High barrier BOPP (WVTR < 0.2) (Normal heat sealing range 85° Celsius) (Optical Density 2.4 to 2.5) | SMA-M3 | (15, 18, 20, 25) | Printing, Lamination for 1 Single/ 2 ply Biscuits, Cookies, Crackers confectionery, Tea bag liners |

We specialize in wide range of products such as SIT 75°C low grade films / 85°C / 95°C / 105°C, High Seal Strength Grade Films, Low COF Bopp Films - < 0.18 and High COF Bopp Films ->0.80, Smooth and Matte Release Grade Film, Matte Metallized Heat Sealable Film, Crack Resistance Metallized Film, etc.

Our group have commissioned the world’s latest state of the art BOPP Film manufacturing facility and our existing BOPP Plant comprises a Bruckner make 10.4 Meter BOPP Film production, M/S. BOBST make 3.65 Meter wide metallizer, Atlas make Primary and Secondary Slitter with annual production capacity of 54,000 MT of BOPP Film and 12,500 MT of Metallized BOPP Film. Secondly the existing Bruckner BOPP Line is capable to produce 10 to 60 Micron Film and same as for BOBST Metallizer Line is capable to produce 10 to 50 micron Film.

- We operate a 10.4-meter wide BOPP film production line from Bruckner, engineered with advanced technology and capable of reaching speeds of up to 600 meters per minute. The line features specially extended MDO and TDO units for superior film stabilization, along with a precision-designed casting unit that enhances the clarity of the printed BOPP film.

- Our co-extrusion setup is optimized for the production of high-quality matte BOPP film, ensuring consistency and excellence across all our BOPP rolls. In addition, our cutting-edge metallizer features Alu-Bond technology, which enhances barrier properties by 4–5 times and metal bond strength by 5–6 times compared to conventional metallized films. It is also equipped with advanced plasma metallizing capability for enhanced performance of multi-colour printed BOPP film used in premium packaging applications.

- Strategically located near the west coast seaport of Mundra, approximately 300 km from our existing manufacturing facility, we are well-positioned for the efficient and timely export of BOPP packaging bags and other film-based solutions for global markets.

What is BOPP film, and why is it used for packaging?

BOPP film (Biaxially Oriented Polypropylene Film) is a durable and lightweight packaging material known for its high tensile strength and clarity. It is widely used in BOPP packaging to protect products while maintaining an attractive appearance. As a leading BOPP film manufacturer, Satyendra Packaging Ltd produces BOPP films with excellent moisture resistance, making them ideal for food, industrial, and retail packaging.

What are the advantages of using multi-colour printed BOPP bags for branding?

Multi-colour printed BOPP bags enhance product visibility and branding by showcasing vivid graphics and text. These bags are preferred by businesses looking for BOPP packaging bags that combine functionality with aesthetics. As a trusted BOPP bags manufacturer in India, Satyendra Packaging Ltd provides premium-quality printed BOPP film solutions that help brands stand out.

How do BOPP film manufacturers ensure high-quality production?

Top BOPP film manufacturers like Satyendra Packaging Ltd use advanced technology and precision-driven processes to produce high-grade BOPP film rolls. Their BOPP film packaging undergoes strict thermal stabilization and slitting processes to ensure strength, smoothness, and consistency. As a reputed BOPP packaging film supplier, they prioritize quality control for industrial and commercial use.

Where can I find reliable BOPP suppliers in India for bulk purchases?

If you’re looking for BOPP film suppliers or BOPP rolls suppliers for bulk orders, Satyendra Packaging Ltd is one of the largest BOPP film manufacturers in India. They provide a range of BOPP poly bags, BOPP printed bags, and BOPP CPP film that cater to diverse packaging needs. Their expertise in biaxially oriented polypropylene film manufacturers ensures clients receive superior products.

What makes metallized BOPP film different from standard BOPP packaging film?

Metallized BOPP film packaging offers enhanced barrier protection compared to standard BOPP packaging film. It uses Alu-Bond technology, improving metal adhesion and strength. Satyendra Packaging Ltd, a renowned BOPP CPP film manufacturer, specializes in metallized BOPP polyester film with advanced properties for high-performance packaging solutions.